A Panoramic Glimpse into the Realm of Landscape Lighting

Landscape lighting, also known as outdoor lighting, is not merely an aesthetic adornment that adds an alluring sparkle to your exterior surroundings. It transcends the conventional definitions of lighting, creating a symphony of light and shadow that can transform your landscape into a nocturnal wonderland.

Embracing the art and science of outdoor illumination can drastically augment the visual appeal of your property whilst enhancing its safety and security. Landscape lighting involves a delicate balance between creative design and technical acumen.

The architecture must be aesthetically pleasing without undermining the functional aspect of providing adequate visibility during darkness. From path lights leading you through enchanting gardens to spotlights highlighting architectural details, each element contributes to the grandeur of well-orchestrated landscape lighting.

However, beyond its ornamental charm lies a labyrinthine network woven with intricacies – an intricate system dictated by advanced electrical engineering principles. This sophisticated infrastructure plays out behind-the-scenes roles in shaping your dreamscape into reality.

The Quintessential Role of Wiring in Landscape Lighting

Delving deeper into the heart of landscape lighting unravels one pivotal component: wiring. Wiring forms the lifeblood that infuses vitality into this spectacular dance ensemble by transmitting electrical current from its source to various light fixtures scattered across your exterior space.

Just like veins distribute blood throughout our bodies, wires transport electricity seamlessly across vast expanses, providing the power required for various types and intensities of lights being incorporated in the design. Therefore, without these intricate networks tracing sinuous paths beneath our lawns and concrete exteriors, our desire for magnificent nighttime landscapes would remain obscure fantasies trapped within realms of imagination.

The gamut of wires used in landscape lighting ranges from thick main feeder cables capable of enduring higher voltages to thinner branches for individual low-voltage fixtures. These wires, encapsulating conductive copper cores within insulative jackets, provide a protective passage for electrical currents, invigorating your exterior lighting.

Moreover, the role of wiring extends beyond just the power supply. The choice and arrangement of wires also dictate the brightness and energy efficiency of lighting systems. For instance, using a proper wire gauge helps prevent voltage drop – a common issue plaguing outdoor lights that leads to dimmer lights and heightened energy consumption. Thus, understanding the ins and outs of wiring becomes indispensable when striving to achieve both aesthetic grandeur and functional brilliance in landscape lighting.

Delving into the Labyrinth of Landscape Lighting Wires

The effectiveness and longevity of your landscape lighting system are inherently linked with the wire that underpins its functionality. Understanding the basics of these wires is critical not only for their installation but also for their maintenance. Landscape lighting wires act as conduits, carrying power from the transformer to each light fixture installed throughout your property.

These wires need to be durable enough to withstand varying weather conditions, hardy enough to resist potential physical damage, and conductive enough to ensure optimal current flow. When designing a landscape lighting system, one must consider the voltage drop across these wires.

Voltage drops occur when electrical power is lost as it travels along the wire due either to wire resistance or high loads from multiple fixtures connected to one circuit. Hence, understanding wire sizes (or gauges), lengths, types, and their related voltage drops can help optimize your landscape lighting system’s efficiency.

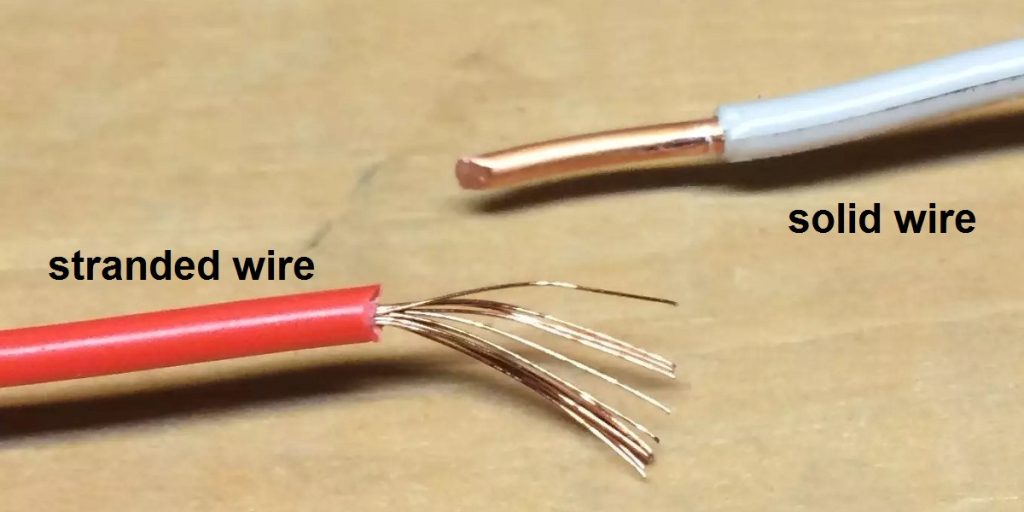

Typically, two key parameters define a landscape light wire – its gauge (thickness) and its type (stranded or solid). These characteristics can influence both the amount of current that can flow through them and their flexibility during installation.

Every Wire Tells a Tale: Types of Wires Used in Landscape Lighting

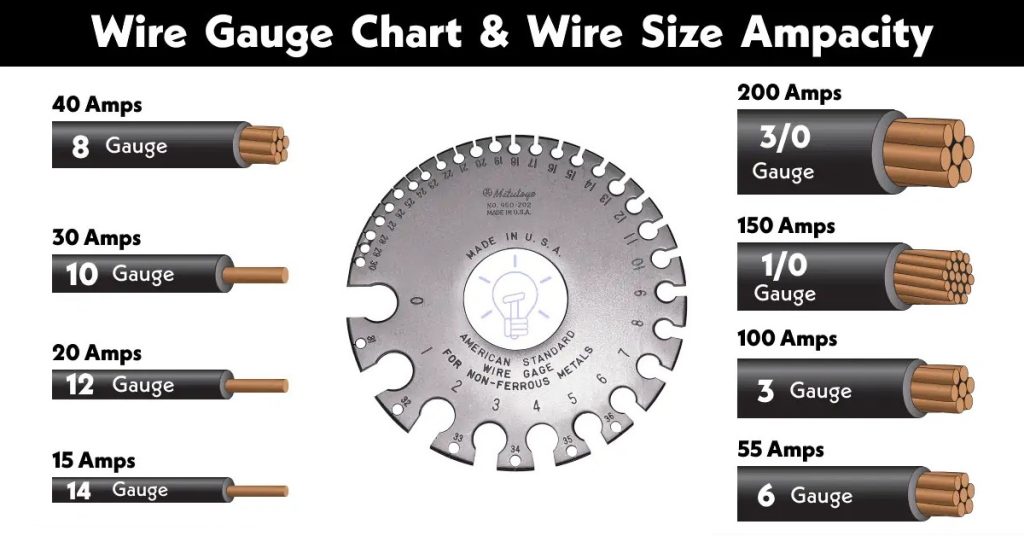

In terms of gauge, most commonly used variants in landscape lighting range from 10-gauge (thicker) to 16-gauge (thinner). Thicker wires have less electrical resistance; hence, they are preferred for longer runs or higher wattage loads since they minimize potential voltage drops. As far as types are concerned, there exist two prominent kinds of landscape lighting wires: stranded and solid.

Stranded wires comprise numerous thin strands bundled together; they offer superior flexibility over solid ones, which consist of a single thick piece of metal wire. While stranded cables might be slightly harder to splice due to their multi-strand construction, this is often outweighed by their increased flexibility and resistance to cracks or breaks, especially in outdoor scenarios.

The Dark Side of Luminescence: Common Issues with Landscape Lighting Wires

Despite the essential role landscape lighting wires play, they are not without their challenges. One common issue that plagues these systems is corrosion. Moisture entering the wire connections can cause corrosion over time, affecting both the wire’s conductivity and fixture performance. This is why it’s crucial to ensure all connections are well-sealed against moisture ingress during installation.

Wire breakage is another persistent issue, often resulting from physical damage like accidental cuts during gardening or degradation due to exposure to harsh environmental conditions. Damaged wires can result in a complete or partial outage of your landscape lighting system.

Voltage drop, as mentioned earlier, is a common but often overlooked problem. Long runs of wire or multiple light fixtures on a single circuit can lead to significant voltage drops, leading to dimmed lights or even shortening the lifespan of your light fixtures.

Improper installation methods, such as poor splicing techniques or incorrect wire gauge selection, can also lead to problems ranging from intermittent fixture operation to potential risks such as fire hazards through overheating. By grasping these fundamental aspects about landscape lighting wires – types and issues – you will be well-equipped with information for effective maintenance of your landscape lighting system.

The Concept of Wire Splicing

Delving into the world of electrical systems, it is evident that several advanced operations and techniques exist, one of which is wire splicing. The concept of wire splicing may at first seem complex, but in essence, it revolves around the principle of joining end-to-end two or more wires to enable a smooth flow of electricity.

Splicing wires is fundamental when alterations to wiring are required without necessitating an entire replacement. Wire splicing is not just a simple cut-and-join operation. It requires precision and knowledge about the properties and behaviors of different types of wires, as well as an understanding of how electrical conductivity works. Properly performed wire splices can result in seamless connections that are as strong and as electrically conductive as uninterrupted lengths of wire.

This technique plays a vital role in establishing substantial connections in various electrical applications such as audio systems, automobiles, household wiring, and even landscape lighting. Although this post centers on landscape lighting wiring specifically, the concept holds true for any scenario where wires must be lengthened or repaired without sacrificing performance.

Decoding Wire Splicing: Definition and Explanation

To explicitly define it, wire splicing is the method employed to combine two or more pieces of wire end-to-end to facilitate continuous electrical flow between them. This process usually involves stripping a segment from their insulation coverings at their ends before intertwining them together either by using an electrician tool known as lineman’s pliers or a twist-on connector (also referred to as a wire nut). The goal during this procedure is essentially twofold: mechanical strength and electrical continuity.

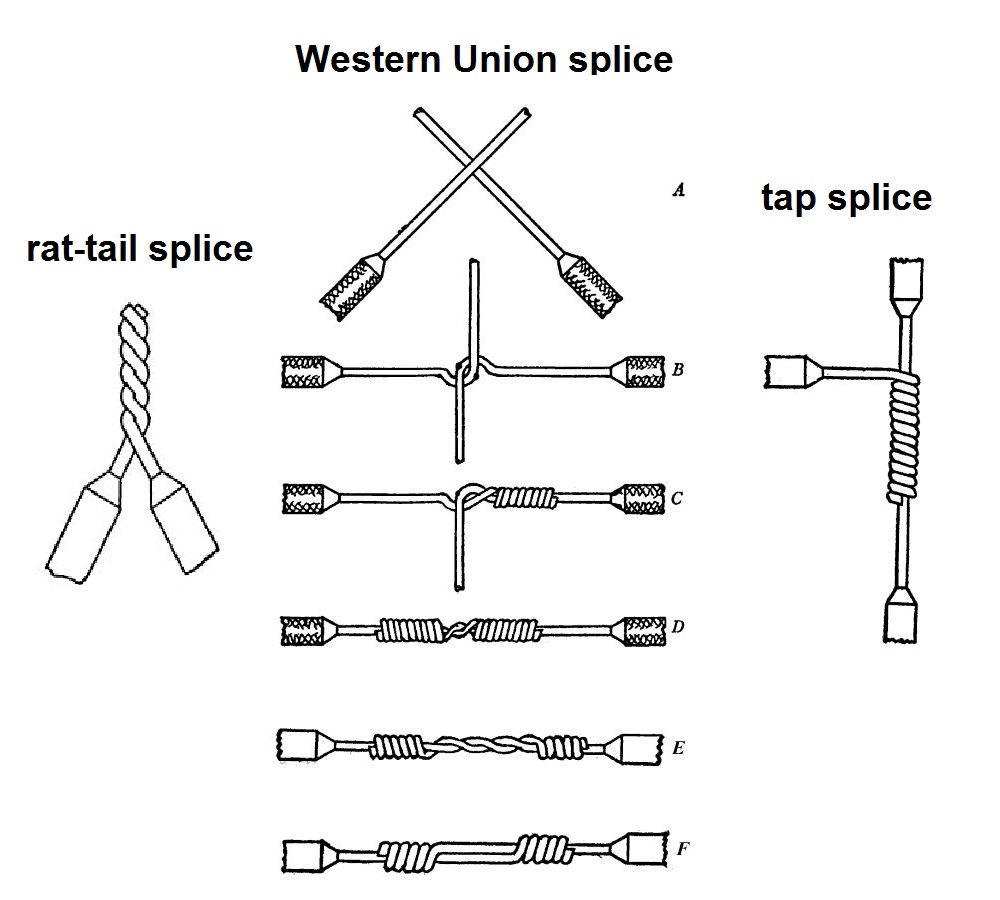

While ensuring the wires do not easily pull apart stresses upon mechanical robustness, maintaining an unbroken current pathway underpins the aspect about electrical continuity. To categorize broadly, there are three types of wire splices: the rat-tail splice, also known as a twist splice or a pig-tail splice, used for connecting two or more wires together in an outlet box; the Western Union splice employed for secure splicing of small solid conductors; and the tap splice that enables a wire connection to a running wire without cutting it.

When executed properly, these techniques result in high-quality wire connections that are both mechanically sturdy and electrically efficient. Thus, the success of any electrical installation or repair task hinges on mastering this pivotal skill.

The Importance and Broad Applications of Wire Splicing

Wire splicing holds considerable importance in electrical applications for various reasons. It allows for adjustments to be made to wiring systems without the need for extensive renovations or replacements. It’s a cost-effective solution when wires have been damaged or when they need to be extended, as is often the case with landscape lighting setups.

Intriguingly, beyond home and automotive repairs, this technique finds its use in telecommunications engineering, where it benefits telephone lines and internet cables, among others. Even on a larger scale, like utility services, including power grid networks, rely on this operation during maintenance works.

In essence, any system involving electrical wires will at some point likely require a splice. Whether it’s adjusting the length of a circuit, repairing damaged sections of wire, or incorporating new components into existing wiring systems, all these scenarios necessitate proficient understanding and execution of effective wire splicing techniques.

Therefore, grasping the nuances involved in proper wire splicing can contribute significantly towards maintaining reliable connections within intricate wiring systems. As we progress through this exploration about landscape lighting wiring specifically, remember that these principles are universally applicable across all realms involving electrical wires.

Can We Splice Landscape Lighting Wires?

The inquiry at hand, “Can we splice landscape lighting wires?” requires a comprehensive exploration. This query, though seemingly straightforward, poses an essential question for landscaping enthusiasts and professionals alike. Splicing, in simple terms, denotes the joining of two or more wires together. Now, to address whether landscape lighting wires fit into this context requires a deeper dive into both theoretical frameworks and practical applications.

Theoretical Possibility: The Science Behind Wire Splicing

Understanding the Art of Conductivity

In theory, splicing landscape lighting wires is entirely possible, and science backs this claim. The fundamentals lie in understanding that wiring essentially facilitates the transfer of electricity – a flow of electrons from one point to another. In terms of landscape lighting systems specifically, low-voltage wires are standardly employed to connect lights to transformers – their source of power.

Interconnections: The Essence of Splicing

Splicing doesn’t interrupt this flow; rather, it offers junction points where these electrons can continue on their path through additional wire lengths added via splices. When well executed with attention to optimal contact between wire strands and appropriate insulation methods post-splice, the continuity remains unhampered.

The Role of Resistance

A key concept involved in understanding splicing’s theoretical feasibility revolves around resistance, which resists electron flow, causing a voltage drop along the line. Although adding more length through splices introduces more resistance technically, as long as overall wire length remains within acceptable limits specified by manufacturer guidelines for specific gauge and transformer wattage combinations used, adequate illumination is achievable without overheating risks.

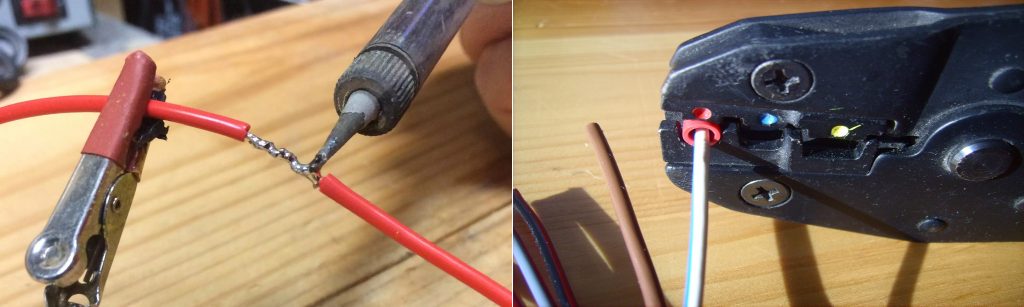

Soldering vs Crimping: Splicing Methods Explored

Known methods for wire splicing include soldering, which creates a robust, low-resistance joint ensuring excellent connectivity, and crimping, where special tools squeeze metal connectors tightly around wires for secure physical bonds. Both methods affirm splicing’s theoretical possibility but bring their own pros and cons that require consideration.

Wire Ratings: Exploring Limitations

Wiring specifications like maximum current ratings also play a part in determining splicing’s feasibility. For landscape lighting wires operating under low-voltage and current, the added load from splices is usually well within safe limits, thus not hindering functionality or safety as long as proper installation techniques are adhered to.

Practical Application: Real-World Scenarios and Examples

A Common Example: Repairing Landscape Lighting

Moving from theory to practical application, wire splicing finds frequent usage when repairs are due on landscape lighting setups. A broken wire or one damaged by accidental cuts during gardening activities can easily be fixed by splicing in a new section of wire with the old one, effectively restoring the circuit’s continuity.

Extending Your Lighting Coverage

Frequently, homeowners desire to extend their landscape lighting to newly installed structures or garden extensions. This would often mean running an entirely new line of wiring from the transformer. With good knowledge of how to properly splice landscape lighting wires, one can seamlessly add additional wiring length to existing lines.

Bursts of Creativity: Customized Lighting Designs

Landscape lighting isn’t merely functional; it’s also an expression of creativity. Often unique garden features necessitate unusual light placement or custom lengths beyond standard offerings. In these instances, precisely executed splices allow for adjustments in wire lengths, facilitating these personalized designs without necessitating complete rewiring jobs.

Navigating Challenges: Troubleshooting Common Issues

While splicing landscape lighting wires is undoubtedly practical, it isn’t without its challenges. Issues can arise from poor connections resulting in intermittent lighting or corroded joints causing complete blackouts. Addressing these problems often involves re-splicing the connection, reinforcing the importance of mastering this essential skill.

Professional Undertakings: Contractor Installations

In professional landscaping undertakings too, wire splices are commonplace. These instances serve to further validate the practicality of splicing landscape lighting wires – as long as they are done properly and safely by knowledgeable practitioners who understand their craft’s technicalities and intricacies.

How to Splice Landscape Lighting Wires: A Comprehensive Guide

The process of splicing landscape lighting wires, while intricate, can be accomplished with a clear understanding and careful execution. The concept of splicing is primarily to join two separate wire ends together, creating a seamless continuation of electrical flow.

This technique comes in handy when you need to extend the reach of your landscape lighting or repair a damaged section. Given its technical nature, it’s crucial to adhere strictly to instructions and safety measures. Before embarking on this task, it’s important to first understand why splicing might be necessary. Over time, wires can wear out due to exposure or physical damage.

Instead of replacing the entire length of wire – which may be costly and labor-intensive – splicing provides an efficient solution by allowing you to repair just the affected section. In addition, effective splicing could also enhance the aesthetics and functionality of your landscape lighting system.

By extending the wiring system effectively through splicing, you can position lights precisely where desired for optimal illumination and visual appeal. It is worth noting that although there are alternatives, such as using connectors or replacing the entire line, these options come with their own set of challenges, including cost implications and compatibility issues, among others, thereby making splicing an attractive proposition in certain scenarios.

However, as mentioned earlier, this process requires technical prowess; hence, it’s not recommended for anyone without basic electrical knowledge or experience. Missteps could lead to not only equipment damage but also personal harm due to electric shock.

The Essential Toolkit: Tools Required for Wire Splicing

Like any other technical task involving electrical systems, having the right set of tools is crucial for a successful wire-splicing process. These tools ensure safety while boosting efficiency during the operation.

The first tool required is a pair of wire strippers. This tool is used to remove the insulation surrounding the conductive material of the wire. Selecting a wire stripper with various gauge notches will allow you to strip wires of different sizes accurately and safely.

Another essential tool is a pair of lineman’s pliers or needle-nose pliers for twisting the bare ends of wires together. Additionally, you’ll need electrical tape for insulating spliced wires, ensuring they are protected from external factors that might cause short-circuits or other damages.

A wire connector or splice cap will also be needed. These come in different types and sizes, with some designed specifically for outdoor use or damp locations – these would be appropriate for landscape lighting systems.

A utility knife may come in handy for precision cutting tasks. Remember to always handle these tools with the utmost care since they can cause serious injuries when misused.

A Step-By-Step Guide to Successful Wire Splicing

Armed with the right knowledge and tools, it’s time to delve into the process itself. Here’s how you can effectively splice your landscape lighting wires:

The first step involves preparing your work area. Ensure it’s clean, well-lit, and free from any potential hazards, such as water sources or flammable materials. It is also important to shut off the electricity supply to avoid accidental shocks.

Next, using your wire strippers, remove about half an inch of insulation from both ends of the wires you intend to splice together. Be careful not to nick or cut into the conductor, as this could affect its performance.

Then comes twisting together the stripped ends firmly (but without excessive force) using lineman’s pliers; this creates a solid physical connection between two wires, ensuring continuous current flow through them after the splicing process is complete.

Once the wires are twisted together, screw a wire connector onto the exposed section until it’s securely in place. Applying an additional layer of electrical tape around the area where the connector and wire insulation meet provides an extra measure of protection.

The final step is to check your work. Ensure that no bare wires are visible and everything is tightly secured. Power up your landscape lighting system to confirm that all lights are working as they should.

Safety Precautions when Splicing Landscape Lighting Wires

Understanding the Risks Involved

The process of splicing landscape lighting wires, while beneficial in numerous ways, is not without its potential hazards. Without a proper understanding and preparation, one may inadvertently create conditions ripe for electrical shorts or fires. It is hence crucial to comprehend these risks before embarking on this procedure.

Firstly, incorrect wire splicing can lead to poor electrical connections. This could result in intermittent lighting performance and can be highly perplexing and frustrating. In worst-case scenarios, it could cause an electrical short circuit, which poses a risk to both your landscape lighting system and property as a whole. Besides that, there’s the inherent danger of dealing with electricity.

Incorrect handling has the potential for causing electric shock, especially if you are working on an active circuit without taking proper safety measures. Furthermore, improperly sealed splices are prone to moisture intrusion, which could lead to corrosion and impair the overall lighting system.

Failure in implementing correct splice insulation is another prevalent risk during wire splicing operations. Exposed wires pose a significant hazard as they can cause short circuits when they come into contact with each other or with wet ground soil.

Last but not least is the risk of fire hazards; loosely connected wires or those with damaged insulation may overheat and spark a fire. This underscores the importance of meticulousness while performing wire splicing tasks.

Essential Safety Measures to Follow

After recognizing these risks involved in landscape lighting wire splicing, it becomes imperative to comply with essential safety precautions in order to ensure successful outcomes. A paramount rule when dealing with any electrical project is turning off the power supply before starting work on any live wires. This simple measure drastically reduces the risk of electrical shock.

In addition, one should make use of insulated tools to provide an extra layer of safety. The act of wearing protective gear cannot be overstated. Rubber gloves and shoes can be particularly beneficial in insulating you from potential electric shocks. Safety goggles are also recommended to protect your eyes from possible sparks or wire fragments.

Moreover, it is crucial to use appropriate connectors and enclosures for splices. These are designed to provide optimal contact between wires, eliminate exposure to outside elements, and prevent them from inadvertently touching other objects or wires, which could result in short circuits.

Any wire splicing process should be followed by a thorough inspection for any signs of loose ends or exposed wires. After the splice is completed and the power turned back on, monitoring the operation will help identify any issues caused by inadequate splicing promptly.

Pros and Cons of Splicing Landscape Lighting Wires

The Advantages: Cost-Effectiveness, Repairing Damaged Lines, Customizing Lengths and more

Splicing landscape lighting wires can convey several notable advantages. First and foremost among these is cost-effectiveness. By splicing wires, you can repair damaged sections without the need for complete wire replacement, leading to significant savings in both material costs and labor charges.

In addition to cost savings, splicing provides homeowners with an efficient method of repairing damaged lines. A broken or frayed wire shouldn’t necessarily mandate a total overhaul of your landscape lighting system. By identifying the fault line and splicing it correctly, one can restore the system to its optimal functionality with minimal fuss.

Wire splicing also introduces an element of customization when installing new lights or modifying existing landscape lighting arrangements. You can splice wires to adjust their lengths according to specific requirements instead of being constrained by standard wire lengths. This flexibility facilitates creativity in designing aesthetically pleasing light displays. Furthermore, spliced connections are generally robust if done correctly.

They maintain good electrical conductivity and are less likely to suffer from intermittent connection issues common with some inferior quality connectors. By mastering the art of wire splicing, homeowners equip themselves with a valuable skill that could prove handy not just in landscape lighting but for a variety of other home electrical repair tasks too.

The Disadvantages: Potential for Poor Connections, Increased Risk if Improperly Done and more

Despite its numerous benefits as outlined above, wire splicing does come with certain drawbacks that warrant careful consideration. Perhaps most significantly is the potential for poor connections if the splice isn’t executed correctly or degrades over time due to environmental exposure. Poor connections not only compromise the effectiveness of your landscape lighting but can also pose severe safety risks.

Improperly done splicing could result in fire hazards due to overheating or even electric shocks, especially if the spliced wires are exposed to moisture or physical damage. Moreover, while wire splicing does provide flexibility in terms of wire length and layout customization, it may also lead to an unsightly mess if not properly planned and executed.

Excessive or haphazardly done splices might mar the aesthetics of your outdoor space. Wire splicing requires a certain level of technical competency, which may be a deterrent for some homeowners. While there are plenty of online guides and tutorials available, proper execution requires practice and patience. A poorly executed splice can do more harm than good.

Although wire splicing can repair damaged lines effectively, it’s not always a long-term solution. Some instances might necessitate complete wire replacement due to extensive wear and tear or significant damage spread over multiple areas along the line.

Alternatives to Wire Splicing in Landscape Lights

The World Beyond Splicing: Exploring Other Methods

While splicing undeniably offers a straightforward, cost-effective solution to many landscape lighting wire issues, it is not the only method available. Indeed, the expansive world of landscape lighting wires holds a plethora of alternatives that are equally compelling.

Connectors present a viable alternative to splicing. Specifically designed for outdoor use, connectors are resilient against harsh weather conditions and the effects of oxidation. They offer an easy and quick way of joining wires by simply pushing them into the connector’s mouth.

Another alternative is using terminal blocks or junction boxes. These devices allow multiple wires to connect at one point, effectively creating a central hub for your landscape lighting system. While this method necessitates more planning and initial set-up than wire splicing, it offers excellent scalability for future expansions.

When damage or degradation becomes too severe for any form of repair work, replacing the entire line may become necessary. This approach ensures that all compromised portions are dealt with conclusively while providing an opportunity to upgrade the wiring system if desired.

Soldering provides another option for joining wires securely, though it requires significant skill and precision. This technique involves melting a filler metal (solder) onto the wire junctions, which upon cooling forms solid connections.

Comparing Apples with Oranges: Splicing vs Alternatives

Having explored various alternatives to splicing in landscape lighting wires, we now delve into how these different methods measure up against each other. Splicing stands out for its simplicity and minimal need for specialized tools or materials – properties that make it highly accessible even to non-professionals. Additionally, this technique enables length customization, which is particularly advantageous when dealing with unique or intricate landscape designs.

On the other hand, connectors offer superior ease-of-use, with their plug-and-play mechanism offering a faster and less technical approach to wire joining. However, they may not accommodate all wire sizes and types, limiting their versatility.

Terminal blocks or junction boxes excel in scalability and organization, turning a potential wire mess into a neat, orderly system. This advantage comes with the trade-off of increased set-up complexity and costs incurred from purchasing the necessary devices.

Line replacement stands as the definitive solution when dealing with severely compromised wires. While effective, this method can be labor-intensive, costly, and potentially disruptive to the existing landscape design.

Soldering boasts of providing some of the most robust and enduring connections but demands skilled hands for proper execution. The need for additional equipment, such as soldering irons, can also add to the overall costs.

In essence, each method bears its own unique strengths and weaknesses that make it more suited to certain scenarios than others. Hence, rather than being seen as competing methods against each other or against splicing specifically, these alternatives should instead be viewed as complementary tools in your landscape lighting toolbox.

Conclusion: Can We Splice Landscape Lighting Wires?

A Reiteration on the Possibility and Implications of Splicing Landscape Lighting Wires

In our exploration of landscape lighting and its intricate wiring, we have discovered that wire splicing is not only a theoretical possibility but also a practical reality. The fundamental principles of electrical connections permit this process, providing opportunities for customization and repair within the realm of landscape lighting. Splicing landscape lighting wires comes with several implications.

On the positive side, it offers a cost-effective solution to deal with wire damages without needing to replace entire lines. It allows greater flexibility to adjust wire lengths according to specific requirements, making it an appealing option for both professional landscapers and DIY enthusiasts.

However, the process is not without its drawbacks. Poor connections can result from improper splicing techniques leading to inconsistent lighting or even system failures. Additionally, there are safety risks associated with electrical work that need careful consideration and precautions. Nonetheless, these challenges do not negate the potential advantages offered by wire splicing in landscape lighting systems.

With adequate knowledge, careful planning, and execution, these hurdles can be mitigated successfully. In essence, splicing provides a viable path towards enhancing your outdoor space’s aesthetic appeal through personalized landscape lighting configurations.

Final Thoughts on When and How to Use Splicing Effectively

The decision to splice landscape wiring should be guided by necessity and practicality. If confronted with damaged wiring or if customization necessitates adjustment in wire lengths, splicing becomes an effective solution. However, it should not be chosen as an easy way out when complete rewiring would offer better longevity or quality of performance.

To execute wire splicing effectively begins by understanding your landscape’s unique requirements and choosing suitable wires accordingly. Procuring high-quality tools designed for electrical work will significantly increase the likelihood of a successful splice.

The actual process must be carried out with precision and care, ensuring secure connections and proper sealing to prevent potential damage from the elements. Although this process can be performed by enthusiastic homeowners, if you are unfamiliar with electrical work or feel uncomfortable performing it, it would be prudent to hire a professional. Experts bring their expertise, skillset, and experience, which can ensure accurate execution while adhering to all safety measures effectively.

Safety cannot be overemphasized in this context. It is paramount that individuals respect the inherent risks associated with electrical projects and prioritize safety measures above all else. Mismanaged wire splicing can lead to hazardous outcomes such as short circuits or even fires.

Splicing landscape lighting wires is a tangible possibility that comes with both its merits and drawbacks. If executed properly under appropriate circumstances, it offers an efficient solution for enhancing your outdoor spaces’ appeal through custom landscape lighting configurations.

Appendix: Enhancing Your Knowledge about Landscape Lighting Wires

As an addendum to the preceding sections of this insightful exposition on landscape lighting wires, the appendix serves to provide additional information that can further improve your understanding. Delving into these auxiliary details can be beneficial in strengthening your knowledge about landscape lighting wires. It can also empower you to make informed decisions when it comes to handling and dealing with these components.

The world of landscape lighting is a fascinating one, filled with myriad components and intricacies that all culminate in the production of beautiful, functional outdoor spaces. Amongst these, the role of wiring is pivotal. Wires serve as vessels of electricity, enabling power flow from sources to light fixtures. They come in different gauges or diameters; notably 12-, 14-, and 16-gauge wires are commonly used for outdoor lighting systems.

When it comes to splicing landscape lighting wires, there are numerous elements at play, including electrical current capacity, wire insulation quality, soil conditions, and physical protection against damage. Wire splicing should only be considered when necessary and done correctly following strict safety guidelines.

Furthermore, understanding how wire connectors work could be another valuable subject matter worth exploring. They facilitate a safe connection between two or more wires without requiring splicing. There are waterproof connectors specifically designed for outdoor use, making them a practical choice for landscape lighting systems.

Beyond the realm of physical components and technical aspects associated with landscape lighting wires lies legislation and regulations that govern their installation and usage. Different regions may have varying codes that dictate how such systems should be installed and maintained, which can influence your decisions regarding whether or not to splice your wiring system.

A Compendium of Additional Insights

In view of enhancing comprehension about this topic further than what has already been covered in previous sections, this part delves into a wealth of supplementary insights that could prove useful. Modern landscape lighting technologies present an interesting area for exploration.

Innovative solutions such as wireless control systems, low-voltage LED lights, and solar-powered fixtures are revolutionizing the traditional landscape lighting scene. These advancements can influence wiring practices, including splicing, making it imperative to keep abreast of trends.

The aesthetic aspect should not be overlooked either. Landscape lights serve twofold purposes: functionality and beautification. The effect of wiring practices on the aesthetic outcome is therefore a significant consideration that underpins decisions like splicing or replacing wires.

Another vital aspect revolves around sustainability. As we become more conscious of our impact on the environment, choosing eco-friendly methods becomes essential. In this regard, understanding recycling practices or disposal guidelines for old or damaged wires forms a crucial part of responsible landscape lighting management.

Ongoing maintenance is another facet to consider in depth. Regular checks and upkeep can prolong the lifespan of your landscape lighting system and lower overall costs in the long run. A well-maintained system requires less frequent wire splicing or replacement, which can be both cost-effective and safety-enhancing.

Knowing what resources are available to help you navigate these aspects would complete your holistic understanding about landscape lighting wire splicing. Whether it’s DIY guides, professional electrician services, or online forums for peer discussions, being aware of what help is out there enables you to effectively handle any challenges you may encounter with your landscape lighting system’s wiring configuration.

You may also be interested in the following posts: