Are LED Strip Lights Able to Adhere to Wood?

A Brief Introduction to LED Strip Lights

Light-emitting diode strip lights are rapidly revolutionizing the world of lighting. These versatile, energy-efficient lights offer creative and practical solutions for a variety of applications. From accent lighting in exterior design to illuminating large commercial spaces, LED strips have emerged as a leading choice in the modern lighting industry.

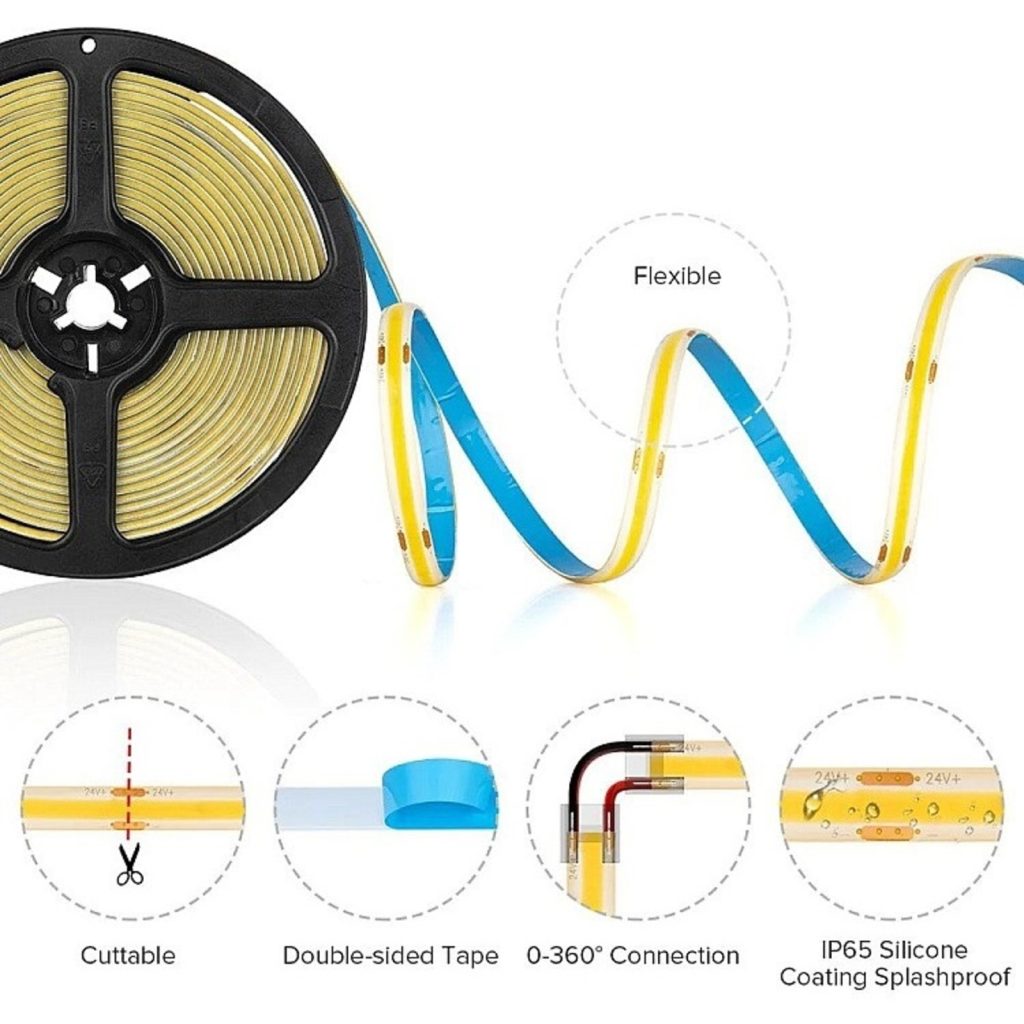

LED strip lights, also known as tape lights or ribbon lights, are essentially flexible circuit boards populated with tiny LED bulbs. These come with an adhesive backing for easy installation and can be cut to any desired length to fit specific needs. The array of available options is staggering – from different colors and brightness levels to even programmable options that can sync up with music or create light patterns.

Shining a Light on the Importance of LED Strip Lights

In today’s technologically advancing society, the importance and benefits of LED strip lights cannot be overstated. Firstly, they are highly energy-efficient, using significantly less electricity compared to traditional forms of lighting such as incandescent or halogen bulbs. This not only results in cost savings but also contributes positively towards environmentally conscious practices.

Additionally, their compact size and flexibility make them easily adaptable for various uses – they can add vibrancy to home decor schemes, provide effective task lighting in workspaces, or add functionality to outdoor landscape lighting setups. One key use is their contribution towards creating interesting landscape lighting schemes.

The flexible nature allows these landscape strip lights to bend around corners, align along pathways, or even highlight specific features within a garden or building facade – bringing an enchanting new dimension under the cover of darkness. Moreover, due to their low heat emission and durable build quality, LED strip lights have an unusually long lifespan compared to other forms of lighting – often lasting upwards of 50 thousand hours!

Addressing the Question: Will LED Strip Lights Stick to Wood?

With all these benefits in mind, it’s not surprising that more and more people are looking to integrate LED strip lights into their homes, gardens, and workspaces. But as the popularity of these lights grows, so do the questions about their usage capabilities. A particularly common query that has garnered interest is ‘Will LED strip lights stick to wood?’

This seemingly simple question has many layers and requires a comprehensive understanding of both LED strip lights and the characteristics of different types of wood surfaces. The answer could potentially expand or limit the application possibilities for these versatile lighting solutions.

Thus, with this post, we aim to clarify every aspect connected to this topic, exploring in depth how well LED strip lights adhere to different wooden surfaces and potential solutions should one encounter adhesion problems. Let us begin this enlightening journey.

Unveiling the Luminary Elegance: LED Strip Lights

LED strip lights, also known as LED tape or ribbon lights, are flexible circuit boards populated by surface-mounted light-emitting diodes (SMD LEDs) and other components that usually come with an adhesive backing. These contemporary lighting devices are characterized by their unmatched versatility, enabling them to be cut to specific lengths using a simple pair of scissors.

These radiant strips have a remarkably slim profile and are virtually invisible when they’re switched off. This makes them perfect for an array of lighting applications, from accent and task lighting to more complex installations like landscape strip lights. Their low heat output and high efficiency contribute to their popularity in both residential and commercial settings.

An Array under the Rainbow: Types of LED Strip Lights

LED strip lights come in myriad varieties, distinguished primarily by color temperature, light intensity or brightness, color rendering index (CRI), strip length, waterproof rating, voltage requirement, and other factors.

The single-color strips usually render either warm white or cool white light, but there are also RGB (red, green, blue) variants that can emit multiple colors. The most versatile type is known as the RGBW (red, green, blue, white), which can create any color, including pure white.

There are also specialty strips that produce UV light for special effects or grow lights for indoor plant cultivation. Landscape lighting often employs waterproof LED strip lights due to their resilience against outdoor conditions.

Beaming Beyond Boundaries: Common Uses & Applications

The applications of LED strip lights span across various fields owing to their unique features, such as flexibility and customizability. They can be used for general room lighting as ceiling coves or floor-level illumination, offering a soft ambient glow.

In the context of landscape lighting, they can breathe life into patios, walkways, or garden features at nightfall through subtle lighting, providing both aesthetic appeal and safety. As landscape strip lights, they can illuminate pathways, stairs, and decks, adding a soft, warm glow to these areas.

LED strips have gained popularity in the commercial sector too, being used extensively for signage or display cases in retail outlets. They are also common in events and stage lighting setups due to their ability to produce vibrant colors and effects.

In the realm of home decor, they are often employed for under-cabinet lighting in kitchens or for highlighting artwork or architectural features. Indeed, the application of LED strip lights is limited only by one’s imagination.

The Science Behind Adhesion

Unraveling the Mechanics of Adhesives

The fundamental principle governing the functionality of adhesives is quite intriguing and captivating. At their core, adhesives work by forming a bond at the junction where two different materials meet. This bond is established via molecular interactions between the adhesive and the material surfaces.

In essence, when you apply an adhesive to a surface, it flows and fills into any pores or irregularities on that surface. When it dries or cures, it ‘locks’ into these crevices, creating a robust physical bond. While this narrative provides a basic understanding, the actual process involves more intricate details.

The strength of an adhesive bond relies heavily on two fundamental forces: mechanical interlocking and intermolecular forces. Mechanical interlocking happens as described above – the adhesive seeps into any pores or unevenness on the surface and forms physical ‘hooks’. Intermolecular forces come into play due to attractions between molecules in both substances.

In addition to these forces, several other elements contribute towards effective adhesion. These include the surface quality of both materials (the adhesive and substrate), curing time of glue (if applicable), amount applied, and pressure exerted during bonding, among others.

A common example that demonstrates effective use of adhesives is landscape strip lights. Their installation often requires them to be stuck onto varying surfaces – from brick walls to wooden decks – using strong adhesives.

Tackling Influential Factors in the Adhesion Process

Different factors can significantly sway how well an adhesive performs its task; temperature and surface type are among those cardinal ones. Temperature plays a dual role in influencing adhesion quality: firstly through its effect on viscosity (which impacts how well an adhesive can spread across and penetrate a surface), and secondly by affecting the curing or drying time of certain adhesives.

Low temperatures can cause some adhesives to become too thick to spread effectively, while high temperatures may accelerate the curing process excessively, leaving insufficient time for the adhesive to form a good bond.

The type of surface is also crucial. Some surfaces are inherently more accessible for adhesives to bond with than others due to their surface energy – the ability of a substance’s surface to attract another substance towards it. High-energy surfaces (like metals) tend to allow better adhesion than low-energy surfaces (such as plastics or wood).

That said, surface treatment can improve adhesion; roughening a smooth surface or using primers can increase its energy and make it easier for an adhesive to stick. For instance, when installing landscape lighting such as LED strip lights on wooden surfaces, prepping the wood via sanding may improve adhesive bonding.

But there’s more to delve into in this specific scenario – hold your horses till we reach that part. In sum, understanding these factors about how adhesives work and what influences their effectiveness can be invaluable not only in selecting the right product but also in ensuring its correct application – for everything from crafting projects at home to sticking landscape strip lights onto patios and terraces or even in high-tech industrial applications.

Compatibility between Wood and LED Strip Lights

A Study of Synergy: Wood Surfaces and Adhesives in LED Strips

The compatibility between wood surfaces and the adhesive used on LED strip lights is a significant factor in determining whether or not the installation process will be successful. In essence, how well these two elements work together depends largely on their mutual interaction, which is influenced by various parameters.

LED strip lights commonly use a self-adhesive backing that sticks to most surfaces. This adhesive medium is generally suitable for wood, as it forms a sturdy bond with the material’s naturally fibrous structure. The uncanny ability of these landscape strip lights to adhere smoothly to wooden surfaces expands their use case scenario tremendously, especially within the realm of landscape lighting.

However, one must also consider the individual properties of different types of wood. Hardwoods such as oak and maple have a dense grain structure that provides an excellent bonding surface for adhesives. Conversely, softwoods like pine or fir may require additional preparation to ensure adequate adhesion.

Certain exotic woods treated with oils or waxes could resist adhesion due to their inherent non-stick properties. In such cases, it may be necessary to lightly sand the surface area where you intend to attach your LED strip lights to improve adherence.

While LED strip lights can generally stick well to most wooden surfaces thanks largely to their adhesive backing designed for universal application, certain types of wood may require additional steps for optimal bonding.

Influencing Factors: Wood Type, Finish, and More

The unique characteristics of different wood types significantly influence their compatibility with LED strips’ adhesive backings. For instance, landscape strip lights could stick better onto some hardwoods compared to softwoods because hardwoods typically possess higher density and a more uniform grain structure, thereby providing a stronger grip for the adhesive.

Furthermore, the finish applied on wood can also impact adhesion. A polished or glossy finish may interfere with the strip light’s ability to firmly adhere. On the other hand, an unfinished or matte surface would usually facilitate better adhesion as it allows direct contact between the strip’s adhesive and the wood fibers.

Apart from these considerations, environmental factors like temperature and humidity also play their part. Warmer conditions may soften the adhesive, affecting its bonding strength, whereas high humidity might hinder proper adhesion by introducing moisture between the adhesive and wood surface.

Understanding these influencing factors can help in making informed decisions about using LED strip lights on different wooden surfaces. This comprehension could be instrumental in amplifying their usage scope in landscape lighting installations whose efficacy is often determined by how well they meld with diverse material types.

In essence, compatibility between wood and LED strip lights is not just about whether they will stick; it’s more about how effectively you can overcome obstacles posed by varying wood types and finishes to ensure optimal adhesion.

Preparation for Perfection: Prepping Wooden Surfaces

If you’re planning to use LED strips for your landscape lighting project on a wooden surface, preparing that surface properly can significantly improve adhesion outcomes. Start by ensuring that your chosen area is clean. Use a cloth to wipe away any dust or debris that may interfere with adherence.

If your wooden surface has been treated or finished already – especially with glossy or oily finishes – lightly sanding it down can create a more suitable foundation for sticking your lights onto it. Choose fine-grit sandpaper (around 120-grit) to avoid causing unnecessary damage to the wood while still removing any unwanted barriers to adhesion.

Post-sanding, a thorough wipe-down is required to remove any residual dust particles. You can utilize a lightly damp cloth for this purpose, but ensure that the surface is completely dry before attempting to attach your LED strip lights.

In more challenging scenarios where the wood’s nature or finish stubbornly resists adhesion, you might consider priming it with an adhesive promoter designed for difficult-to-bond surfaces. Such promoters can significantly improve the bonding strength between your LED strips and the wood surface.

By conducting adequate preparation of your wooden surface before installation of landscape strip lights, you can significantly enhance their adhesion potential and longevity. Remember that thoroughness and patience in these preparatory stages often yield remarkable results in your landscape lighting project.

Case Studies & Practical Examples: The Revealing Tales

Success Stories: LED Strip Lights and Wood in Harmony

One of the most inspiring success stories comes from a homeowner who transformed their backyard deck into an enchanting oasis using LED strip lights. After proper surface preparation, they attached the lights along the perimeter of their wooden deck, creating a soft border glow. This innovative approach for landscape lighting not only provided necessary illumination but also elevated the visual aesthetics of their outdoor space.

In another instance, a café owner used LED strips to create an inviting ambiance within their establishment. The vintage wood-paneled walls were adorned with warm white LEDs, which beautifully highlighted the wooden textures while providing adequate lighting. The application was so successful that it increased customer footfall and became a signature design element of their café.

A craft enthusiast shared his experience of using LED strips to accentuate his custom-made wooden bookshelf. By affixing cool white LEDs along the borders of each shelf, he achieved an aesthetic yet functional lighting solution that showcased his book collection brilliantly.

Pitfalls in Process: Understanding Challenges

Applying LED strip lights on wood is not always smooth sailing; some users have faced challenges during installation. Landscape strip lights placed on garden pathways made from chips of bark mulch tended to peel off due to irregular surfaces and moisture exposure. Moreover, direct sunlight led to degradation in adhesive quality over time.

Inside homes, too, there have been instances where adhesive-backed LED strips failed to stick properly on textured or untreated wooden surfaces. The rustic charm of such surfaces often comes with adherence issues due to lack of smoothness or presence of dust/dirt.

In commercial settings like bars or restaurants with high ambient temperatures and humidity levels owing to busy kitchens nearby, adhesives tended to lose their grip. Such factors, although not common in households, are significant for businesses using LED strip lights as a decor element.

Problems Solved: Finding the Bright Solutions

In response to these challenges, there have been innovative solutions. For instance, the homeowner with the landscape lighting issue solved it by attaching his landscape strip lights to a thin wooden plank instead of directly on the bark mulch path. This provided a smooth surface for better adhesion and protected the LEDs from ground moisture.

The householders facing issues with textured or untreated wood surfaces found success by either sanding down the surface to make it smoother or sealing it before applying the strip lights. Both methods greatly improved adhesion by providing a cleaner and smoother application surface.

In commercial settings with high temperature and humidity levels, users countered adhesive failures by using mounting clips or brackets. These created a secure hold that could withstand harsher conditions without compromising on aesthetics.

To conclude, while questions might arise about whether LED strip lights will stick to wood surfaces, real-world examples clearly illustrate that they can – given proper surface preparation and mindful consideration of ambient conditions. Supplementing adhesive-backed LEDs with additional accessories like mounting clips can also circumvent common installation hitches.

Tips for Applying LED Strip Lights on Wood Surfaces

Adhesive Affairs: Choosing Right for Your Light

While most LED strip lights come with a self-adhesive backing, the efficacy of this adhesive can vary depending on the brand and model. Some may stick perfectly to wood surfaces, while others might require additional support. In instances where you find the adhesive inadequate, consider supplemental adhesion materials.

A robust double-sided tape or a layer of silicone adhesive can significantly enhance grip. Ensure any additional adhesives you choose are safe for both wood and electrical components and can withstand any environmental conditions your landscape lighting might be exposed to.

When choosing your landscape strip lights, check customer reviews and product descriptions to get an idea of the quality of the built-in adhesive before making a purchase. Remember, in some cases, nails or screws could be used as an equally effective alternative to traditional adhesives – just keep in mind that puncturing the light strip itself could damage it permanently.

Clean Slate: Preparing Your Wooden Surface

Ensuring your wooden surface is properly prepared before applying your LED strip lights is paramount for successful application. Firstly, start by cleaning the surface thoroughly; use a mild detergent solution or rubbing alcohol to remove any dust, dirt, or grease that could impede adhesion.

Once cleaned, make sure the surface is completely dry before proceeding. Depending on environmental conditions, including fluctuating temperatures or high humidity levels common in outdoor landscape lighting installations, allowing drying times overnight might be necessary.

Surface roughness can also play a significant part in how well your light strips adhere to wood. A smoother surface generally facilitates better bonding, so sanding may improve adhesion, especially if working with rougher woods like oak or mahogany.

Consider applying a sealant if your wooden surface doesn’t already have one. Not only will this create a smoother bonding surface, but it also protects the wood from moisture damage, which is beneficial for landscape strip lights exposed to the elements.

The Practical Journey: Step-by-Step Guide to Effective Application

The first step to applying your LED strip lights to wood is to plan your installation thoroughly. This means deciding where you want the light strips to go, measuring the length required accurately, and marking out any corners or curves.

Next, prepare your strip lights. Measure and cut them as necessary. Most LED strip lights can be cut at certain points along their length – typically marked by a scissors icon or a line across the strip. It’s important not to cut anywhere else because it could damage the lights’ circuitry.

Then comes sticking time. If using additional adhesive, apply it evenly along the back of your light strips, ensuring there are no bumps or lumps that may disrupt uniform contact with the wooden surface. Carefully peel off any protective film on the self-adhesive backing just before application.

Place one end of the LED strip at your starting point and press firmly but gently onto your surface, sliding along in a straight line if possible – applying too much force could potentially harm some delicate LEDs! Ensure that each section adheres fully before moving onto the next one; this helps avoid air bubbles or creases forming under the strips.

Once installed, power up your landscape lighting for an initial test run before securing any fixtures permanently with screws or clips if needed. Enjoy your bright new addition! The process may seem complex but actually becomes quite second nature after a few attempts. Applying LED strip lights on wood surfaces can be achieved effectively with proper preparation and techniques – shedding new light on how you illuminate and highlight features in wood-centric landscapes.

Exploring Alternative Methods When Direct Adhesion Fails

Opting for Mounting Brackets or Clips: An Efficient Solution

In scenarios where direct adhesion of the LED strip lights to the wooden surface fails, mounting brackets or clips can prove to be a viable solution. These accessories offer a sturdy and reliable means to secure LED strip lights. Mounting brackets and clips are usually designed in a way that they can hold the light strips firmly against any surface, including wood.

Mounting brackets are particularly useful for installing landscape lighting, as they ensure the light strips are fastened securely even in outdoor conditions. The installation process is straightforward: simply screw the bracket into place and then clip in your LED strip light.

This method guarantees a more permanent solution compared to adhesives, which can lose their stickiness over time. Landscape strip lights secured with mounting brackets provide an aesthetically pleasing sight after dusk, lighting the surroundings with a warm and welcoming glow.

Moreover, using these materials also simplifies maintenance since you can easily unclip and reclip the LED strips whenever required. The only potential downside of using this method is that it might leave visible marks on your wooden surfaces due to drilling holes for screws.

However, if done meticulously with careful planning regarding the placement and visibility of these fittings, this can be minimized. It’s worth mentioning that while considering this option, one must take into account both aesthetics and functionality to achieve optimal results with their lighting installation projects.

Creating Grooves in Wood: A Seamless Integration of Lights

A more involved yet highly effective method involves creating grooves in the wood where you’d like your LED strip lights affixed. By embedding light strips within these crevices, you craft an almost seamless integration of lighting onto your wooden surface.

This method might seem complex initially, but the resulting visual appeal is worth the effort. The landscape lighting setup using this technique provides an even and harmonious lighting without any protruding elements.

However, this method requires a certain degree of craftsmanship and familiarity with tools such as routers or chisels. To create these grooves, you must mark out where you want your LED strip lights to go on your wooden surface. Once marked, use a suitable tool to carve out a shallow trench just deep enough for your LED strip to sit in. Ensure that the groove width matches the width of your LED strip for a snug fit.

Landscape strip lights embedded into wooden surfaces present an elegant sight, especially when they are part of outdoor decking or garden features. The light emanates from what seems like the wood itself, creating an enchanting ambiance that invites admiration from onlookers.

It’s important to finish by securing the LED strips within these grooves using appropriate adhesives or clear resin to protect them from dust and moisture. A layer of varnish over the top can help blend these fittings further into their wooden surroundings.

Doubling Down with Double-Sided Tape: An Adhesive Alternative

Another alternative when direct adhesion fails involves using double-sided tape or other adhesive products designed specifically for heavy-duty applications, such as affixing LED strip lights onto wood surfaces.

The procedure is quite simple: first clean and prepare the wood surface thoroughly; then apply one side of the double-sided tape onto it; finally peel off its protective layer and stick your LED light strips over it. This method proves particularly useful when dealing with tricky areas where brackets cannot be used or grooving isn’t possible.

When employing this method for landscape lighting needs, ensure you select weather-resistant double-sided tape for outdoor applications. This will ensure the bond remains strong despite exposure to rain or changes in temperature.

Landscape strip lights adhered using double-sided tape can provide an even distribution of light, making your outdoor spaces look more inviting and secure. This technique is relatively easier and quicker compared to using brackets or creating grooves in the wood, without sacrificing too much on aesthetics.

While LED strip lights don’t always stick well directly to wood surfaces, you have several formidable alternatives at your disposal – from utilizing mounting brackets or clips and creating a groove in the wood to embed the light strip to employing double-sided tape for secure adhesion. The key is choosing a method that best matches with your particular scenario and aesthetic preferences.

Conclusion: Will LED Strip Lights Stick to Wood?

The Luminary Verdict: Revealing the Answer

After an exhaustive exploration of LED strip lights and their compatibility with wood, we can confidently conclude that, yes, LED strip lights can indeed adhere to a wooden surface. This is predominantly due to the adhesive backing that most strip lights come equipped with.

However, the success of this adhesion largely depends on certain factors such as the type and finish of the wood and the preparation of the surface prior to application. It’s also clear that these luminary additions are not just exclusive for other surfaces but also a viable option for those looking to enhance their woody interiors or exteriors.

In fact, when correctly installed, LED strip lights can transmute any mundane wooden piece into an aesthetically pleasing spectacle. Landscape strip lights have been particularly successful in this regard, with many finding value in using such lights for their outdoor wooden landscapes.

Sailing into Light: Guiding Advice for Navigating Your Lighted Path

Embracing LED lighting solutions isn’t merely about adhering a strip of diodes onto a surface; it encompasses understanding your unique space and choosing a suitable lighting design. It involves knowing how to optimize your landscape lighting effectively using these versatile strips. Therefore, if you are contemplating installing these radiant bands on your wooden surfaces – be it furniture or outdoor decks – remember: preparation is key!

A good cleaning routine will go far in ensuring optimal adhesion, while considering factors like wood type and finish will further enhance the likelihood of success. If you encounter difficulties with direct adhesion or are dealing with a more delicate or textured wood type, fear not! Alternatives such as mounting brackets or double-sided tape have proven effective. You might even consider carving out grooves in which to lay your light strips for an embedded look.

In Retrospect: The Journey of Light

Retracing our steps, we have established that LED strip lights can indeed adhere to wood surfaces. These radiant bands of light hold transformative potential for any interior or exterior landscape, offering an enchanting blend of practicality and aesthetics.

The variety of available LED strip lights allows you to find the perfect match for your application needs. With careful consideration, proper preparation, and a dash of creativity, you are well-equipped to embark on a successful journey towards lighting your wooden spaces with LED strip lights. Here’s to lighting up your world in ways you’d never imagined possible before!

You may also be interested in the following posts: