Master Waterproofing Landscape Lighting Connectors: A How-To Guide

The Crucial Importance of Waterproofing Landscape Lighting Connectors

The value of landscape lighting cannot be overstated. It beautifies outdoor spaces, enhances property value, and contributes significantly to home security. However, the performance and longevity of your landscape lighting system hinge on one tiny but vital component – the connectors.

Amidst their exposure to external elements, waterproofing these connectors is not just a procedure; it’s a necessity. Waterproofing landscape lighting connectors extends their lifespan and ensures their optimal function.

Without this protective measure, your once vibrant nocturnal oasis can be reduced to patches of darkness. The hidden aesthetics of your garden that are revealed after sunset with strategic lighting become jeopardized when the connectors fail due to water damage.

Moreover, waterproofed connections guarantee safety. Electricity and water are formidable foes; an inadequately protected connector can cause a short circuit or even result in an electrical fire – an unquestionable risk to your home’s inhabitants and structure.

Imagine how it would feel gazing out at an enchantingly lit garden after dusk or walking through your beautifully lighted pathway only for the lights to abruptly go out due to faulty connectors. The charm dissipates instantly, replaced instead with annoyance or even worry.

The repercussions are not just aesthetic or safety-oriented; they’re also financial. Continually replacing damaged connectors or entire fixtures can add up financially over time – a cost that could have been avoided with proper waterproofing at the outset.

Ephemeral Glow: Unmasking the Perils of Water Intrusion

Unprotected landscape lighting connectors exposed to moisture present a clear and alarming danger: water intrusion. This menace can sneakily undermine the efficiency of your outdoor lighting system without you realizing until it’s too late. Surely you may think a little water couldn’t possibly harm sturdy electrical connectors?

But alas, even the smallest amount of water can generate enough conductivity to cause a short circuit. This spontaneous event often results in permanent damage not only to the connector but also to the entire lighting fixture.

Further, continuous exposure to moisture can cause corrosion in landscape lighting connectors. Corrosion is an insidious process that gradually degrades and weakens the metal parts of the connector. Over time, this corrosion can lead to component failure and necessitate replacement.

Another concern with water intrusion is its potential for causing electrical fires. Water entering a connector can create an unexpected pathway for electricity that could lead to overheating or even sparks that ignite nearby flammable material. Let’s not forget about freeze-thaw cycles in colder regions.

Water seeping into a connector can freeze and expand during cold conditions, potentially cracking or damaging the unit. When it thaws, it provides further opportunities for additional water intrusion, perpetuating a destructive cycle.

Understanding Landscape Lighting Connectors

A Comprehensive Look at Landscape Lighting Connectors

Landscape lighting connectors serve as the critical juncture between the source of electricity and the landscape lighting fixtures. They are specially designed to ensure a steady flow of electrical current from the power source to your landscape lights, enabling them to brighten your outdoor space. Their primary function is not merely restricted to providing a conduit for electricity; they also serve as protection, preventing possible short circuits or electrical leaks that could lead to severe damage.

The connectors work in tandem with other components of your landscape lighting system, like cables and transformers, creating a complete circuit. They are meticulously engineered for outdoor settings, ensuring that electricity can be safely channeled even in adverse weather conditions.

The Role of Lighting Connectors in Shaping Your Landscape Aesthetics

A poignant aspect that often goes unnoticed about these little devices is their influence on shaping the aesthetics of landscape lighting. Depending on how they’re structured and where they’re placed, landscape lighting connectors can dramatically affect light distribution patterns. This subtle artistry imbues each corner of your garden, patio, or backyard with unique luminous character.

Yet it’s not just about enhancing beauty; it’s also about safety. Properly installed and maintained connectors ensure there are no sudden blackouts or flickering lights that compromise visibility at night, averting potential tripping hazards among many other risks associated with poorly lit exteriors.

Unveiling Different Types of Landscape Lighting Connectors

Among the wide array available on the market today, landscape lighting connectors generally fall into three main categories: piercing connectors (also known as clamp-style), twist-on wire nuts, and push-in-style connectors.

Piercing or clamp-style connectors feature sharp prongs that penetrate through wire insulation upon installation, establishing direct contact with the conductor inside. They offer convenience and speed, as they often do not require stripping the wire insulation before use.

Dissecting the Mechanics of Twist-On Wire Nuts

Twist-on wire nuts are another common type of landscape lighting connector. They work by twisting together the exposed conductors of two wires and then screwing on a plastic cap for stability and protection. This style is favored for its reliability, as it creates a secure connection that is less likely to come undone compared to other methods.

However, working with twist-on wire nuts requires more preparation – namely, stripping away the insulation from each wire you’re connecting. This extra step makes installation slightly more time-consuming but can lend itself to a more reliable connection in the long run.

Parsing Push-In Style Connectors

The third type is push-in style connectors, which are known for their easy installation process. As implied by their name, these connectors work by pushing stripped wires into holes in the connector body until they ‘catch’. A firm yank-test should confirm a secure connection.

While push-in connectors provide simplicity and speed in installation, their downside lies in occasional reliability issues over time due to corroding or loosening. However, with careful installation and regular maintenance checks, they can be just as effective as other connector types.

Each landscape lighting connector carries its own set of advantages and potential drawbacks. The choice primarily depends on your specific landscape lighting setup and personal preferences concerning installation ease and long-term maintenance.

The Imperative for Impermeability: Understanding the Need for Waterproofing

Water, in its myriad forms, ranks among the most pernicious adversaries of electrical systems. Landscape lighting connectors, which form crucial linkage points in outdoor illumination setups, are particularly susceptible to water’s insidious ingress. By breaching the sanctity of these connectors, water can wreak havoc in ways subtle yet significant.

From corrosion to short-circuits, the damage inflicted by water on landscape lighting connectors extends both to their structure and function. Corrosion is one primary way that water compromises landscape lighting connectors’ integrity.

Water triggers an electrochemical reaction that erodes metals used in connector manufacture, such as copper or brass. Over time, this corrosive process can lead to a breakdown of these vital components and resultantly cause failure in your lighting system.

Besides corrosion, another deleterious effect of water intrusion is the risk of electrical shorts and faults. When moisture gains entry into a connector’s interior circuitry through cracks or weak seals, it may trigger an unintended path for electricity, leading to a short circuit that could eventually cause permanent damage.

In addition to physical damage incurred by the connector itself, there are also safety risks posed by water penetration into electrical systems – most notably electric shocks or fire hazards due to sparks caused by short circuits. As such, waterproofing becomes not just an optional add-on but an absolute necessity when it comes to maintaining outdoor electrical installations like landscape lighting connectors.

The Vagaries of Weather: Dissecting Impact on Outdoor Electrical Systems

The second part of our discussion delves into weather conditions – another key element with pivotal influence on outdoor wiring systems like landscape lighting connectors. Outdoor environments expose these connections not just to rainfall but also to humidity variations, temperature fluctuations, and even snowfall in certain regions.

Each of these climatic agents has its own distinct implications for the health of outdoor electrical systems. Rainfall is typically the most conspicuous threat to outdoor connectors. The direct impact of water can lead to the aforementioned issues like corrosion and electrical faults. Rapid changes in weather, such as a sudden rainstorm, can present an acute risk.

Humidity, while often overlooked, is another important factor that can negatively impact landscape lighting connectors. High humidity levels can accelerate corrosion and expedite wear and tear on exposed metal parts. It also raises the ambient moisture content, which could seep into any vulnerable spots in your connector.

Temperature fluctuations too play their part in undermining the integrity of your electrical system. Frequent transitions between high and low temperatures can cause materials to expand and contract, leading to loosening or cracks over time, which eventually become hotspots for water entry.

Understanding and preparing for the full spectrum of weather conditions is crucial for ensuring a robust, long-lasting outdoor lighting setup that consistently lives up to its intended purpose.

Basic Tools and Materials for Waterproofing

A Comprehensive Compendium of Necessary Tools

To successfully conduct a waterproofing operation, it is crucial to avail yourself of the proper tools. A primary tool one should procure is a waterproofing sealant. This substance plays an instrumental role in the process, serving as a barrier against moisture intrusion. It typically comes in liquid form, which solidifies upon application to create an impermeable layer over your landscape lighting connectors.

Secondly, silicone tape is another indispensable tool in your waterproofing toolkit. Known for its exceptional resistance to water and its ability to provide insulation, this adhesive tape adheres seamlessly to itself without leaving any sticky residue. Its flexibility also allows it to conform easily to irregular surfaces, making it ideal for wrapping around various types of landscape lighting connectors.

A brush or applicator is needed for the smooth and even application of the waterproofing sealant. The size of the brush should correspond with the size of your connector – smaller brushes for smaller connectors and vice versa.

Aside from these primary materials, having a clean cloth or rag at hand will be useful for initially cleaning your connectors before applying anything to them. A soft-bristle brush can also be used if there’s hard-to-remove dirt or grime on your connectors.

Remember that preparation is key in any task such as this one. Make sure you have all necessary tools within arm’s reach before you start working so you can perform each step seamlessly and efficiently.

Safety Equipment: A Critical Component

It is paramount that safety remains at the forefront when embarking upon tasks involving electrical components like landscape lighting connectors. The first line of defense against potential hazards includes wearing rubber gloves when handling outdoor electrical connections – not only do they insulate against electric shock, but they also offer protection from harmful substances contained in some types of sealants.

Another essential safety gear is protective eyewear. While waterproofing landscape lighting connectors may not seem like a task that presents a high risk to eyes, inadvertent splashes of sealant or sudden gusts of wind can propel particles towards the eye. Protective eyewear keeps your eyes secure from such potential risks.

In addition to gloves and eyewear, wearing a face mask or respirator is also recommended, especially when working with sealants that emit strong fumes. Not only does it prevent you from inhaling toxic fumes, but it also keeps you from accidentally ingesting any small particles that might be present in the air while you’re working.

An often overlooked piece of safety equipment while doing electrical work outdoors is proper footwear. Rubber-soled shoes provide excellent insulation, reducing the risk of electric shock, especially if you’re working on moist ground. Although it may not count as ‘equipment’, always remember to turn off and unplug any electrical devices before starting work on them.

This can’t be emphasized enough – many accidents occur simply because people forget this crucial step in their eagerness to get the task done. Each piece of this safety equipment plays an integral role in mitigating risks during the waterproofing process, thereby ensuring both successful completion and personal well-being throughout.

Step-by-Step Guide to Waterproof Landscape Lighting Connectors

Cleaning and Drying: Preparing the Groundwork for Impeccable Waterproofing

The initial step in the process of waterproofing landscape lighting connectors starts with meticulously cleaning and drying the connectors. Prior to any waterproofing technique, it is significant to ensure that the area is free from dirt, dust, or grime. Using a small brush or a can of compressed air can significantly aid in removing accumulated particles on the surface.

Once cleaned, a thorough drying process is vital. Moisture trapped within can potentially compromise your waterproofing attempt. Dry it naturally if time permits; else employ a hairdryer or heat gun on low setting for faster results.

In both scenarios, be gentle and avoid damaging the connector’s structure while cleaning or drying. Remember that meticulous preparation not only aids in better adherence of waterproofing agents but also ensures that you are not sealing in harmful elements like moisture or debris within.

Besides cleanliness, inspect your landscape lighting connectors for possible cracks or damages that could make them susceptible to water intrusion. If found faulty, consider replacement before proceeding further.

Sealing It Right: The Application of Waterproof Sealant

Moving forward with our endeavor to safeguard landscape lighting connectors from water damage involves applying an appropriate waterproof sealant. Start by selecting a high-quality outdoor silicone sealant designed specifically for waterproofing purposes. Prior to applying, put on your safety gear, including gloves and safety glasses.

Squeeze out an adequate amount of sealant onto your connector, making sure all crevices are covered evenly and completely. The application should be thick enough that water cannot penetrate but not so thick as it obstructs the proper function of the connector when reassembled.

Smooth out this sealant layer for even coverage. Allow the sealant to cure as per the manufacturer’s instruction, usually for 24 hours or until it is completely dry to touch. It is essential not to rush this process since any disturbance may result in an ineffective waterproofing barrier.

Furthermore, avoid laying a thick layer of sealant all at once. Instead, consider applying multiple thin layers, allowing each to dry before applying the next. This method can significantly enhance waterproofing efficacy.

Double Security: Wrapping Connectors with Silicone Tape

To augment the effectiveness of our waterproofing scheme and ensure longevity, we employ a second line of defense – wrapping connectors with silicone tape. Select a quality silicone tape with high resistance to heat and water.

Start by cutting an appropriate length of tape – just enough to cover your connector entirely without excessive overlapping. Begin wrapping from one end and proceed towards the other, ensuring tape adheres well without air bubbles or creases in-between layers.

Cover all areas meticulously, leaving no room for water intrusion. Silicone tape does not have a sticky side like traditional tapes but adheres well when wrapped tightly around an object, forming a waterproof barrier; hence, it is crucial that you wrap it perfectly tight around your connectors.

If your landscape lighting setup is faced with heavy rain or snow conditions frequently, you might want to double-wrap tape layers for added protection and peace of mind. However, ensure that this doesn’t interfere with the functioning or assembly of your connector system.

The Final Outcome: Testing Your Waterproofing Efforts

With our tutorial on how to waterproof landscape lighting connectors lies perhaps one of the most pivotal steps – testing your efforts for success. Post application of sealant and wrap, allow some time before running test trials; haste here could ruin your meticulous work so far.

You can initially perform a dry test: visually inspect the connector for any possible exposed areas or crevices that might have been missed during the process. Ensure all surfaces are evenly covered and the sealant is cured adequately.

Following this, conduct a wet test. Spray water gently onto your connectors, ensuring all parts get wet. Observe carefully for any water seeping through or beading up on the surface hinting towards an inadequate waterproof barrier.

If you notice any leakage during these tests, revisit previous steps and rectify errors accordingly. Perfect waterproofing is not about getting it right in one go but about persistent trials to achieve a seamless shield against water intrusion.

Special Tips & Techniques for Effective Waterproofing

A Compilation of Expert Tips for a Successful Waterproofing Process

When it comes to ensuring the successful waterproofing of landscape lighting connectors, it’s not solely about using the right materials and tools; technique also plays a pivotal role. Having a steady hand and applying an even coat of waterproof sealant can effectively ward off water intrusion. It’s important to allow ample time for the sealant to cure fully before testing the light fixture.

Additionally, when wrapping your connector in silicone tape, ensure it’s done tightly but without overly tightening, as it might damage the insulation layer. The tape should overlap with each wrap around by at least one-half its width. This method ensures that no gaps are left through which water could potentially penetrate.

The process shouldn’t be rushed. Taking your time during each step will aid in guaranteeing a secure and lasting watertight seal. Furthermore, don’t skip any steps or take shortcuts – each part of this process is crucial towards achieving an effective waterproof state.

Bear in mind that while doing this task during warm weather conditions is ideal for drying purposes, extreme heat can affect the effectiveness of certain sealants and tapes. Therefore, opt for a mild day if possible or consider working during cooler parts of the day, such as early morning or late evening.

Last but not least, after applying sealant and wrapping with silicone tape, don’t forget to visually inspect your work regularly over time. This way you can catch any potential signs of wear-and-tear early on before they become more serious issues.

Maintaining Your Landscape Lighting Connectors’ Waterproof State Over Time

Once you’ve successfully waterproofed your landscape lighting connectors, routine maintenance checks should be carried out to ensure they remain in a waterproof state over time. A good rule of thumb is to inspect your outdoor electrical systems at the beginning and end of each season.

During these inspections, look for any signs of wear-and-tear on the silicone tape, such as peeling or cracking. If you notice any potential weaknesses, it’s best to strip off the old tape and replace it with a fresh layer. Likewise, check for any degradation or discoloration in the sealant; if found, clean off the old sealant and reapply a new coat.

Be sure to also check for any corrosion on the metal parts of your connectors, as this can indicate water intrusion. If corrosion is present, it’s advisable to replace the affected connectors entirely.

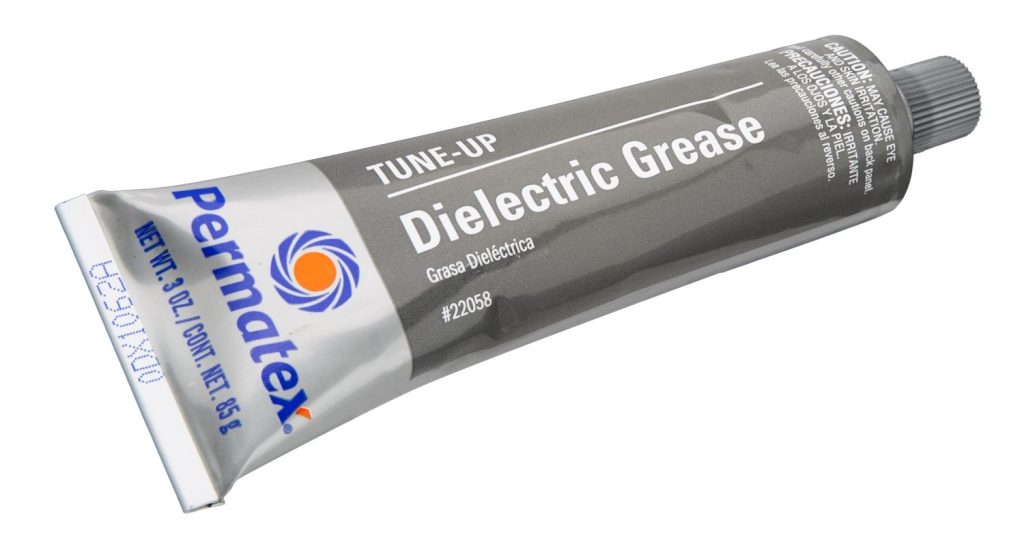

In addition to regular checks and maintenance, consider using products like dielectric grease on your connectors’ metal parts during installation. This type of grease can provide an extra layer of protection against moisture while also enhancing electrical conductivity.

Remember that even though landscape lighting systems are designed for outdoor use and exposure to weather elements, providing them with some form of shelter or cover can significantly reduce wear-and-tear caused by environmental factors. Therefore, if possible, consider installing protective covers over areas where connectors are concentrated.

Common Mistakes in Waterproofing Landscape Lighting Connectors

The Faux Pas of Waterproofing Procedures

First and foremost, one common error committed during waterproofing procedures is the inadequate preparation of the connectors. Many individuals overlook the importance of thoroughly cleaning and drying the connectors before applying any sealant. Dust, grime, or moisture trapped underneath can lead to ineffective sealing, which eventually allows water intrusion.

Another frequent mistake lies in the hasty application of waterproof sealant. This often results in uneven coverage, creating vulnerable spots that might allow water to seep through. Alongside this is the excessive use of sealant – a misconception that more sealant equals greater protection. In reality, an excessive amount may make it harder for proper curing to occur.

Improper use of silicone tape also makes its way into the list of common blunders made during waterproofing landscape lighting connectors. Merely wrapping it around without stretching can lead to gaps where moisture can enter. Furthermore, ignoring overlaps by securing ends at different points sets up a direct pathway for water.

Neglecting a post-waterproofing test often leads many down a path filled with recurring electrical issues caused by unseen water damage. Many assume that once they’ve waterproofed their landscape lighting connectors, their work is done; however, comprehensive verification should be conducted to confirm its efficacy.

Navigating Around the Pitfalls: Tips for Avoidance

To avoid these mistakes, begin with meticulous preparation: clean and dry your landscape lighting connectors fully before attempting to apply any product. Ensure there’s no residue or moisture present on your materials that could compromise your waterproofing efforts.

When applying your waterproof sealant, patience and precision are virtues worth practicing here; ensure even distribution across all surfaces without resorting to excesses – leave no corner unattended nor drowned in product surplus.

The correct usage of silicone tape involves slight stretching, which ensures a snug fit around your connectors. Overlapping the tape creates a more effective barrier against moisture. Be sure to secure the ends at a common point for a continuous, unbroken water shield.

Conducting a post-waterproofing test is not just an option; it’s an imperative step that allows you to confirm the success of your waterproofing efforts. When testing, ensure your connectors are completely dry and then examine for any signs of leakage or damage.

Through knowledge and careful application of these steps, you can effectively safeguard your landscape lighting connectors from water intrusion and extend their lifespan in your outdoor spaces, paving the way for luminous landscapes, regardless of weather conditions.

Advanced Waterproofing Techniques

An Odyssey into Advanced Waterproofing Methods

The basic waterproofing techniques outlined are wholly sufficient for most typical landscape lighting scenarios. However, when dealing with particularly complex or high-risk landscape environments, delving deeper into advanced waterproofing methods may be necessary. For instance, if the lighting system is exposed to more extreme weather conditions or situated in areas with high moisture levels, such as near bodies of water or in regions with heavy rainfall.

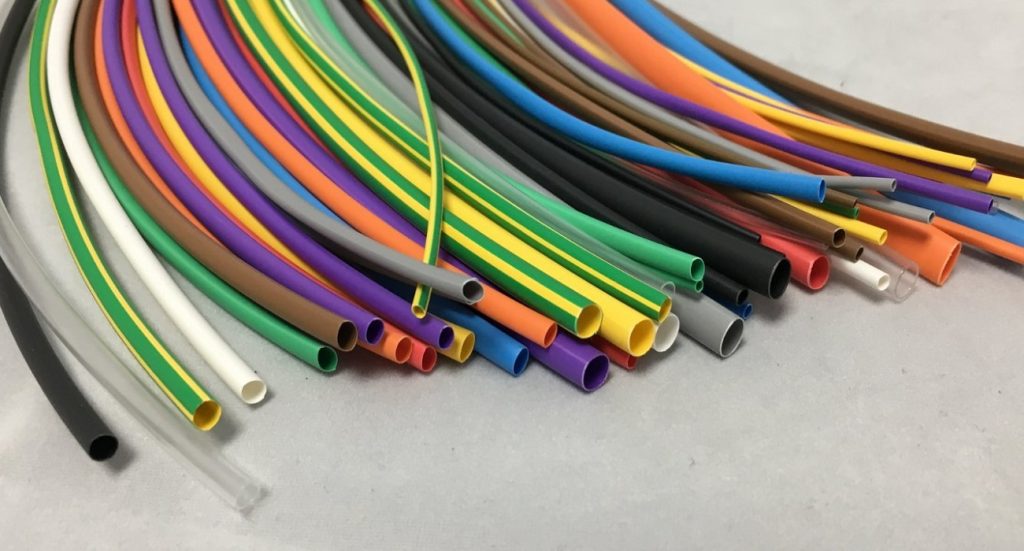

One such advanced technique involves the use of heat shrink tubing. This type of tubing is made from a thermoplastic material that shrinks in diameter when heated. This allows it to form a tight seal around the connector, providing an additional layer of protection against water intrusion.

Another sophisticated method is potting the connectors inside a protective enclosure filled with a special compound – usually silicone, epoxy, or urethane-based – which solidifies and forms an impenetrable barrier against moisture. This process can be labor-intensive but offers superior protection even in challenging environmental conditions.

There’s conformal coating – a thin protective film that can be sprayed or brushed onto the connectors’ surface. Often composed of acrylic, silicone, or urethane compounds, this coating shields connectors from corrosion caused by moisture without interfering with their electrical conductivity.

When Professional Help Becomes a Necessity

While DIY waterproofing is indeed feasible and cost-effective for many homeowners, there are situations where hiring a qualified professional becomes indispensable. One such instance would be when dealing with intricate lighting systems that require specialized skills and knowledge beyond that possessed by an average homeowner.

If you find yourself needing to apply advanced techniques such as potting or conformal coating but lack the technical know-how necessary to perform them accurately and safely, it might be time to call in an expert. Professionals trained in these techniques will not only ensure they’re performed correctly but will also provide the peace of mind that comes with knowing your landscape lighting system is adequately shielded from damaging water intrusion.

Moreover, if you’re dealing with a large-scale or commercial project where a significant number of connectors need to be waterproofed, a professional can save you vast amounts of time and effort. Professionals are experienced in handling such tasks efficiently and effectively.

In addition, if the landscape lighting system is part of an integrated smart home setup or operates on high voltage, it’s advisable to hire professionals for waterproofing tasks due to the complexity involved and potential safety risks. Having a professional handle these advanced waterproofing techniques can often end up saving money in the long run by preventing damage due to improper installation and reducing the need for costly repairs or replacements down the line.

A Luminary Farewell: Culminating Thoughts on Waterproofing Techniques

There’s No Substitute for Suasion: The Imperative of Proper Waterproofing

In the realm of outdoor lighting, one cannot overstate the importance of effective waterproofing techniques. As we have navigated through this enlightening discourse, it has become increasingly clear that the longevity and functionality of your landscape lighting connectors critically hinge on your waterproofing proficiency.

This essential safeguard not only preserves the luminous aesthetic of your external space but also circumvents potential hazards linked to water damage and electrical malfunctions. When properly executed, waterproofing fortifies your landscape lighting connectors against the relentless onslaught of weather elements, extending their lifespan and maintaining their radiant glory.

More than a simple protective measure, it is an investment in the enduring resplendence of your property that brings peace of mind while saving time and resources in potential repair or replacement costs. It is essential to remember that every connector you protect is a step further from the precipice of premature failure.

This exercise may seem laborious at first blush but gradually morphs into an act of care for your living space. The triumph lies not merely in comprehending these techniques but in implementing them successfully – transforming theory into practice with dexterity and finesse.

Sparking Joy: An Optimistic Viewpoint on Proper Waterproofing Techniques

As we draw this discussion to a close, let us view our newfound knowledge as empowering rather than intimidating. While volumes could be written about advanced waterproofing techniques and pitfalls to avoid, the heartening reality remains that even basic understanding and implementation go a long way in enhancing protection.

For every obstacle encountered along this enlightening journey towards better waterproofing practice, there’s an opportunity for growth and improvement; each failure can become a stepping stone towards success; each challenge overcome illuminates our path with wisdom gained.

Such is the transformative magic of learning and growth, of turning mere connectors into resilient beacons that withstand rain and shine alike. Indeed, the power to protect your landscape lighting connectors lies in your hands.

Your journey towards becoming a skilled practitioner of waterproofing techniques has just begun. As you continue to hone these skills, rest assured that your efforts cast an enduring glow over your surroundings – a testament to the beauty that persists when we strive against the odds.

Conclusion: How to Waterproof Landscape Lighting Connectors?

In essence, waterproofing landscape lighting connectors is more than just a technical procedure; it’s an opportunity to enhance safety, longevity, aesthetic appeal, and ultimately enrich our interaction with our living spaces. As you venture forth in this luminous pursuit armed with knowledge and renewed confidence, remember that every radiant evening under the glow of well-maintained lights is a testament to your diligence and skill. Go forth with assurance, knowing you’ve harnessed the power to keep darkness at bay – one waterproof connector at a time.

You may also be interested in the following posts: